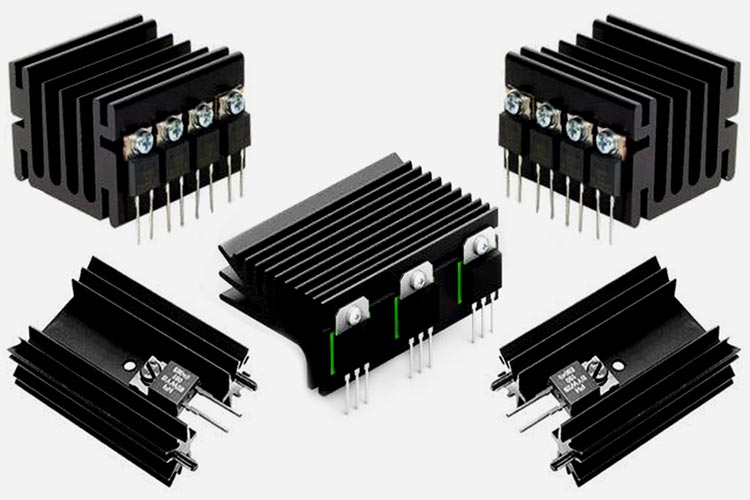

In today’s tech-driven world, managing heat efficiently is essential for devices to perform well and last longer. From building CPU coolers to keeping LED lights from overheating, understanding how heat works is important, but can be challenging.

Enter the heat sink calculator, a handy tool that makes heat dissipation calculations easy for both engineers and hobbyists. This blog post explores why understanding heat sinks matters and how this simple tool can improve your designs and boost your confidence.

What Is a Heat Sink Calculator?

A heat sink calculator is a tool that helps you pick the right heat sink to keep electronic parts from getting too hot. You enter information like how much heat the part produces, the temperature limits, the airflow, and the material used. The calculator then shows how well the heat sink will cool things down, helping you choose the best one for your project.

Why It’s Useful

- Provides quick, early estimates of how well your cooling will work.

- Helps you make better design decisions, like choosing materials, fin spacing, and airflow.

- Many heat sink calculators are free and available on manufacturer websites.

- Usually accurate within about 10% for common designs.

A heat sink calculator offers a fast, reliable starting point for thermal design, helping you size components, pick materials, and understand airflow needs before diving into advanced modeling or prototyping.

How the Calculator Works , Key Principles

- Thermal Resistance Network

Think of heat flow like electricity moving through a circuit. The calculator breaks down the heat path into parts:

- Junction-to-Case Resistance: Heat flow from the chip to its case.

- Case-to-Sink Resistance: Heat flow from the chip’s case to the heat sink.

- Sink-to-Ambient Resistance: Heat flow from the heat sink to the air around it.

The calculator adds these resistances to find how much the temperature will rise for each watt of heat produced. This helps ensure the chip doesn’t overheat.

- Material and Shape

Provide details about the heat sink’s material (for example, aluminum or copper) and its design features (like the size and spacing of fins). This helps the calculator identify the most effective heat sink to move heat away from your device.

- Airflow and Cooling Type

The calculator lets you specify if the cooling is by natural air movement or by fans pushing air (forced convection). This shows how different cooling methods change heat sink performance.

- Thermal Interface Materials (TIMs)

TIMs are special materials placed between the chip and heat sink to fill tiny gaps and improve heat transfer. The calculator considers TIM type and thickness to see how they impact cooling.

Heat Sink Calculator uses these core ideas, thermal resistance, materials, design, airflow, and interface materials, to give accurate estimates of heat sink performance. This helps engineers create cooling solutions that keep electronic parts reliable and long-lasting.

Benefits of Using a Heat Sink Calculator

- Saves Time and Cuts Down Trial-and-Error

Heat sink calculators give quick estimates of how well a heat sink will work. This speeds up design by reducing the need for lots of physical testing and redesigns.

- Helps Choose the Right Heat Sink Accurately

Helps choose the right heat sink accurately by using precise details like power, temperature, and materials to find the best size and type for keeping your component safe and working well.

- Prevents Overheating and Damage

Prevents overheating and damage by keeping parts cool, which helps avoid failures and makes your electronics last longer.

- Optimizes Size, Weight, and Cost

Calculators help balance cooling performance with space, weight, and budget limits, so you get efficient cooling without overspending or wasting space.

- Great Learning Tool

Students and engineers can use these calculators to see how heat moves, why materials matter, and how design choices change cooling. This makes learning about heat much simpler.

Using a heat sink calculator makes designing electronic cooling faster, more accurate, and smarter. It helps create reliable, efficient systems while also teaching important thermal management principles.

How to Use a Heat Sink Calculator

- Enter Device Power and Environmental Info

- Heat Source Power: Put in the maximum heat your component produces (in watts). You’ll usually find this in the component’s datasheet.

- Maximum Case Temperature: Enter the highest temperature the component’s case can safely reach.

- Maximum Ambient Temperature: Input the hottest temperature of the environment where your device will work.

- Thermal Budget: The thermal budget is the allowed temperature rise, calculated by subtracting the ambient temperature from the maximum case temperature.

- Volumetric Thermal Resistance: Volumetric Thermal Resistance measures a heat sink’s cooling power. For moderate airflow, values range from 80 (small heat sinks) to 150 (large heat sinks).

- Altitude Adjustment: Reduce the thermal resistance value by about 10% for every mile above sea level because thinner air cools less effectively.

- Check the Required Thermal Resistance

After inputting your data, the calculator will tell you the thermal resistance (θ) your heat sink needs to have. This helps you pick a heat sink that can properly cool your component.

- C. Pick the Right Heat Sink or Cooling Method

- Material: Choose a heat sink made from materials that conduct heat well, like aluminum or copper.

- Size: Make sure the heat sink fits inside your device and has enough surface area to cool the heat generated.

- Airflow: Think about whether your device will rely on natural airflow or use fans. Fans push air and cool much better than natural airflow alone.

- Mounting & Interface: Use good thermal interface materials (TIMs) and make sure the heat sink is firmly attached to the component for best heat transfer.

- Update and Recalculate if Design Changes

If your design changes, like if your component produces more heat or the environment gets hotter, make sure to update the details in the calculator and recalculate. This ensures you pick the right heat sink to keep your device cool and working properly.

Conclusion: Why Use a Heat Sink Calculator?

A heat sink calculator is a powerful, easy-to-use tool that helps you design better cooling solutions for electronic devices. It simplifies complex heat calculations by letting you input key details like power, temperature limits, airflow, and materials. With this, you can quickly find the right size and type of heat sink to prevent overheating and keep your components running safely and efficiently.

A heat sink calculator saves time, cuts guesswork, and helps balance cooling with size, cost, and weight. It’s useful for engineers and a great learning tool for students and hobbyists wanting to understand thermal management.

By updating your information whenever your design changes, you make sure your cooling system keeps working well. Using a heat sink calculator helps you design better cooling faster and more accurately, so your electronics stay safe, last longer, and work their best.